Industrial environments have changed significantly over the past decade. Production systems now demand higher precision, tighter energy control, and greater flexibility than traditional fixed-function setups can provide. As automation becomes more integrated into daily operations, control infrastructure must adapt to support these evolving requirements.

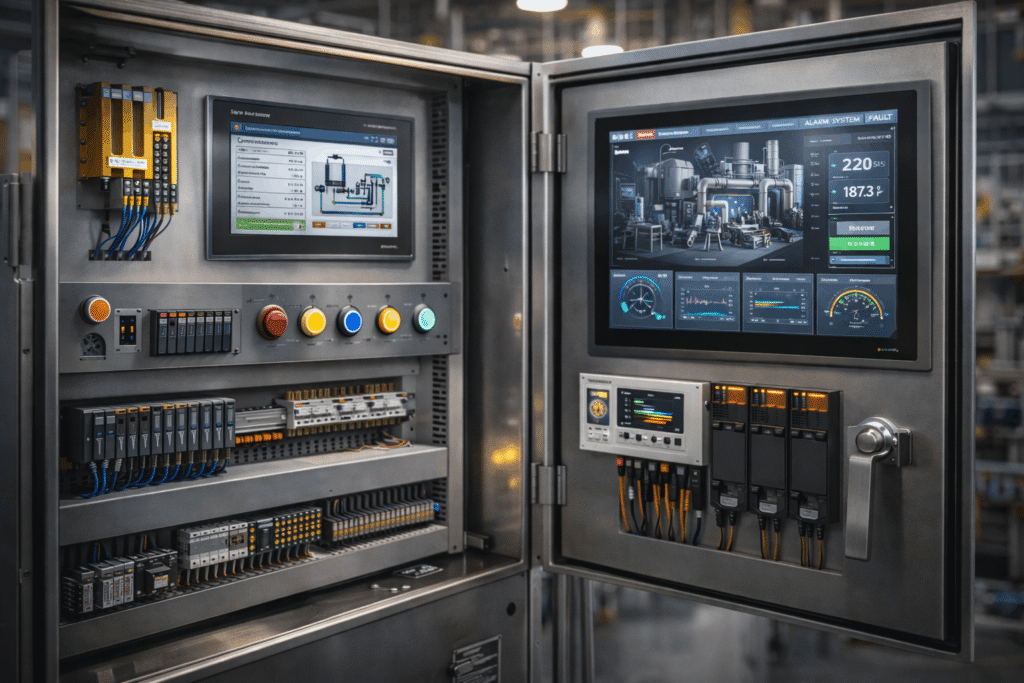

At the center of this shift are custom control panels designed to align with specific process needs rather than generic configurations. Unlike off-the-shelf assemblies, tailored panels account for operating conditions, load characteristics, communication requirements, and maintenance expectations from the start.

Well-designed control panels improve system responsiveness, reduce downtime, and support scalable automation.

Elements of Effective Control Panel Design

Successful control panel design begins with a clear understanding of the application. Engineers must account for electrical loads, environmental conditions, control logic, and safety requirements before selecting components or defining layouts.

Correct Component Sizing and Selection

Component selection plays a critical role. Drives, contactors, breakers, relays, and power supplies must match the voltage, current, and duty-cycle requirements. Oversizing leads to unnecessary cost, while undersizing introduces reliability risks. Balanced selection ensures consistent performance without excessive complexity.

Structured Panel Layout for Reliability

Panel layout also affects reliability. Logical spacing improves airflow, reduces heat buildup, and simplifies wiring. Proper separation between power and control circuits minimizes electrical noise and improves signal integrity, particularly in automation-heavy systems.

Thermal Management and Environmental Protection

Thermal management remains a core design consideration. Industrial panels often operate in high-temperature or dusty environments. Adequate ventilation, enclosure selection, and heat dissipation planning protect sensitive electronics and extend service life.

Clear Documentation and Labelling Practices

Documentation and labelling further support long-term usability. Clear schematics, wire markers, and component identification make commissioning, troubleshooting, and future modifications more efficient. These details reduce maintenance time and help prevent errors during service events.

How VFD Panels Support Automation

Motor-driven systems form the backbone of industrial automation, and variable-frequency drives play a central role in controlling speed, torque, and energy consumption. A properly engineered VFD panel integrates these drives into the broader control architecture while ensuring protection and stability.

VFD panels manage incoming power, regulate motor output, and protect both the drive and motor from electrical faults. By controlling acceleration and deceleration, they reduce mechanical stress and improve process consistency across conveyors, pumps, fans, and material handling equipment.

Automation systems rely on VFD panels for precise speed control. Integration with sensors, PLCs, and supervisory systems allows drives to respond dynamically to process conditions. This level of control improves efficiency and reduces unnecessary motor operation during low-demand periods.

VFD panels also support operational flexibility. Parameter changes can adjust system behaviour without mechanical modifications. This allows facilities to adapt to changing production requirements while maintaining stable operation.

From an energy perspective, VFD-based control reduces power consumption by matching motor output to actual load demands. This contributes to lower operating costs and supports broader energy management strategies within the facility.

Integration, Wiring, and Long-Term Reliability

Even the best components cannot compensate for poor integration or wiring practices. Proper system integration ensures that control panels communicate effectively with motors, field devices, and higher-level automation systems.

Wiring quality directly affects reliability. Correct conductor sizing, proper termination, and secure routing reduce voltage drops, overheating, and signal interference. Consistent wiring practices also make panels easier to service and expand.

Cable management plays an essential role in long-term performance. Organized wire routing improves airflow and reduces the risk of insulation damage. Segregating power and control wiring minimizes electromagnetic interference, which is especially important in high-speed or precision automation environments.

Grounding and bonding are equally critical. Proper grounding protects personnel, stabilizes reference signals, and reduces the likelihood of electrical noise affecting sensitive control circuits. These practices support predictable system behaviour and compliance with industrial electrical standards.

Reliability also depends on designing panels with maintenance in mind. Accessible components, spare capacity, and standardized layouts simplify future upgrades and repairs. Panels built for long-term use anticipate change rather than forcing complete replacement when requirements evolve.

By focusing on integration quality from the start, facilities avoid common issues that lead to premature failures or extended downtime.

Conclusion

Modern industrial operations require a control infrastructure that can support precision, flexibility, and reliability under demanding conditions. Thoughtfully engineered panels provide the foundation for efficient automation, stable motor control, and predictable system behaviour.

By combining careful component selection, structured layouts, robust wiring practices, and scalable integration, custom control panels help facilities meet current performance demands while preparing for future expansion. When designed with real operational needs in mind, control panel systems become a long-term asset that supports uptime, efficiency, and consistent industrial performance.