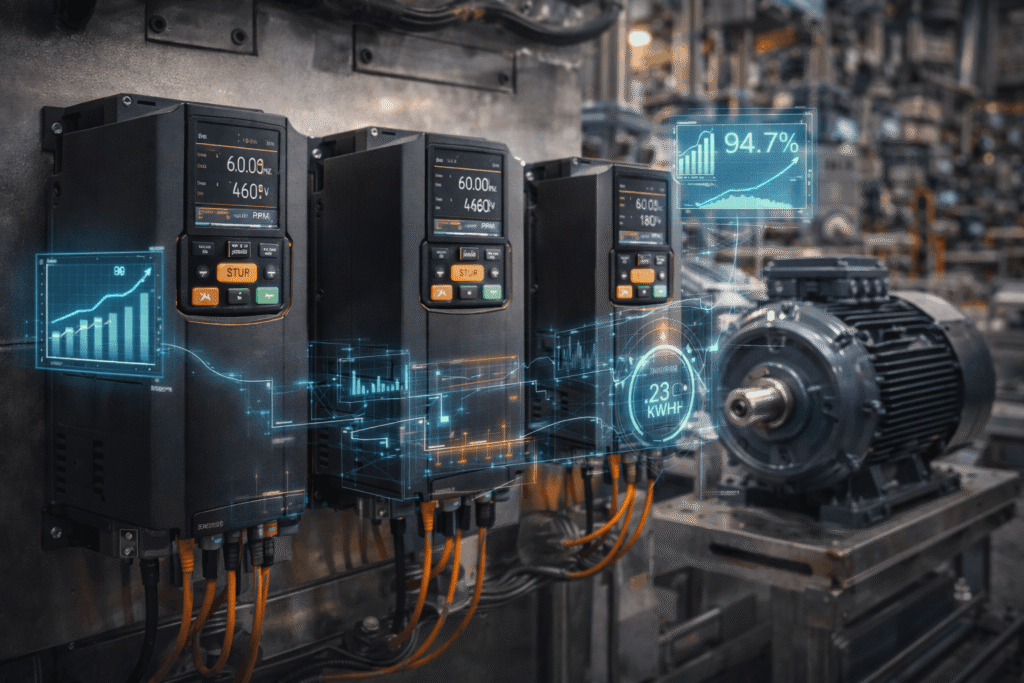

Industrial operations are under increasing pressure to reduce energy consumption while maintaining consistent output and equipment reliability. Traditional fixed-speed motor systems often operate inefficiently, running at full capacity even when demand is low. This has accelerated the adoption of AC drives across a wide range of industries.

By controlling motor speed and torque in real time, AC drives allow equipment to operate closer to actual load requirements. This reduces wasted energy, minimizes mechanical stress, and improves overall process control. As energy costs rise and operational efficiency becomes more critical, AC drive technology continues to shape the future of motor-driven systems.

Energy and Performance Benefits in Industrial Settings

One of the most significant advantages of AC drives is their ability to reduce energy consumption. Motors controlled by drives only use the power required for the task at hand, rather than operating continuously at full speed. This is especially beneficial in applications such as pumps, fans, compressors, and conveyors.

Beyond energy savings, AC drives improve motor performance by enabling smooth acceleration and deceleration. Controlled ramping reduces inrush current and mechanical shock, extending the life of motors, couplings, and driven equipment.

Thermal management also improves with drive-controlled operation. Reduced electrical and mechanical stress lowers heat generation, helping motors maintain stable operating temperatures. This contributes to improved reliability and fewer unplanned shutdowns.

In environments where load conditions fluctuate frequently, AC drives provide consistent torque control, ensuring stable performance even under varying process demands.

Important Features for Selecting AC Drive Suppliers

Selecting the right drive solution involves more than choosing a product with the correct power rating. Reliable AC drive suppliers offer technical expertise, application knowledge, and ongoing support that extend beyond initial installation.

Drive compatibility is a key consideration. Drives must integrate seamlessly with motors, automation systems, and existing electrical infrastructure. Features such as communication protocols, feedback options, and protection functions play an essential role in system performance.

Thermal design and environmental ratings also matter. Industrial settings may expose drives to dust, moisture, or temperature extremes. Proper enclosure design and cooling capabilities help ensure long-term reliability.

Support services further differentiate suppliers. Access to commissioning assistance, troubleshooting guidance, and replacement components reduces downtime and supports long-term system stability.

Use Cases Across Manufacturing and Processing

AC drives are widely used across manufacturing sectors to improve efficiency and control. In material handling, drives regulate conveyor speeds to match production flow, reducing wear and energy waste.

In processing industries, AC drives support precise control of mixers, pumps, and fans. This enables consistent product quality while adapting to changing throughput requirements.

Automated production lines rely on drives for synchronized motor control, allowing multiple systems to operate together efficiently. This coordination improves productivity and reduces mechanical strain.

HVAC and utility systems also benefit from drive technology, particularly where variable airflow or fluid movement is required. Drives allow these systems to respond dynamically to environmental conditions and operational schedules.

Conclusion

As industries continue to prioritize efficiency, flexibility, and reliability, AC drive technology is increasingly important in motor control strategies. By enabling precise speed regulation and reducing unnecessary energy use, industrial AC drives help facilities optimize performance while managing operating costs.

When properly selected and applied, AC drives support long-term system stability and improved equipment lifespan, making them a foundational component of modern industrial motor systems.