Laboratories across genomics, diagnostics, life sciences, and drug development share a common challenge: scaling workflows without increasing errors or overextending budgets. Automated solutions have become essential for meeting these growing demands. Whether preparing PCR plates or executing complex high-throughput screens, automated liquid handling enables labs to move faster, reduce manual variation, and maintain strong data accuracy.

However, investing in new robotics can be cost-prohibitive for many facilities. Certified pre-owned systems offer a compelling alternative, pairing OEM-level reliability with significantly reduced financial strain. For labs upgrading outdated technology or expanding capacity, certified pre-owned equipment delivers trustworthy performance—without the premium price tag.

Understanding Automated Liquid Handlers and Their Role in Research

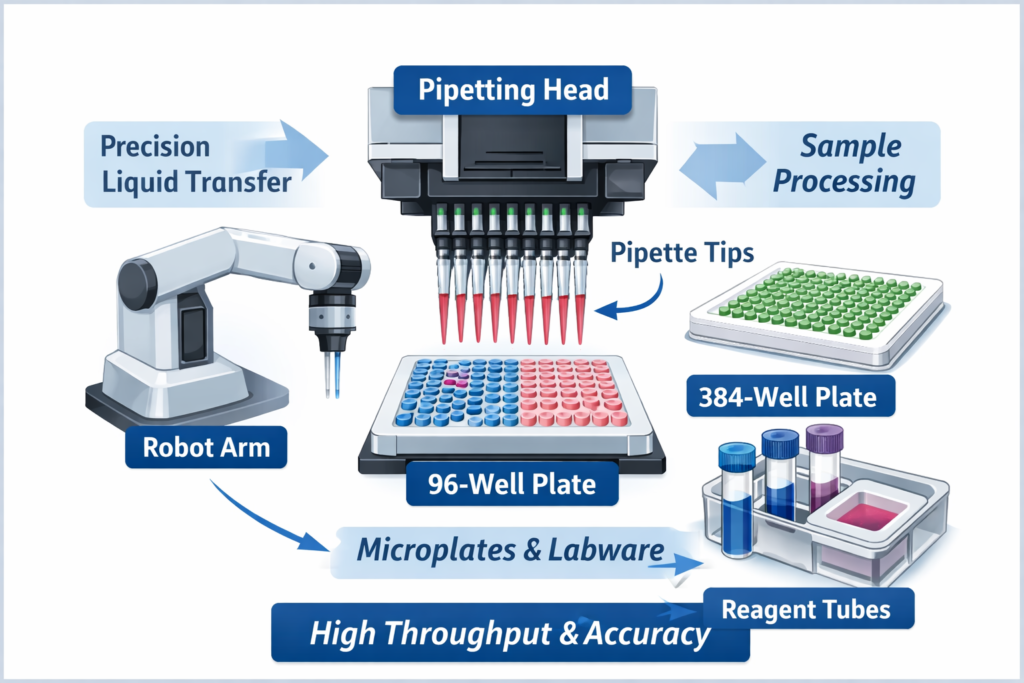

Automated liquid handlers perform precise pipetting tasks using robotics, controlled motion, and software-driven protocols. These systems handle everything from simple dispense-and-mix workflows to highly complex multi-step procedures. As research pipelines scale, liquid handlers become foundational tools for reducing manual labor and maintaining experimental consistency.

Key lab activities supported by liquid handler equipment include:

- PCR setup and qPCR preparation

- Next-generation sequencing library prep

- Serial dilutions

- Reagent normalization

- ELISA plate preparation

- Cell-based assay setup

- Drug discovery screening workflows

- High-throughput biochemical assays

By eliminating manual pipetting fatigue and variation, automated systems provide consistent, repeatable results even across thousands of samples. This reliability is why automated liquid handling remains central to modern research operations.

What Makes Equipment “Certified Pre-Owned”

Not all pre-owned equipment is equal. Certified pre-owned automation undergoes a meticulous process that ensures every component operates at manufacturer-level standards. This process includes:

- Complete mechanical and electrical inspection

Technicians evaluate motors, actuators, pipetting heads, sensors, and communication boards. - Replacement of worn or failing parts

Items like seals, tubing, filters, valves, and robotic joints are replaced when needed. - Full calibration and volume accuracy verification

Dispense accuracy is validated, ensuring precise microliter-to-milliliter transfers. - Functional testing with real protocols

Systems run through simulated workflows to confirm reliability. - Final QA validation against OEM specifications

Performance reports confirm the equipment meets expected benchmarks. - Professional cleaning and refurbishment

The unit is restored cosmetically and structurally for optimal operation.

This rigorous process ensures a certified pre-owned system is scientifically dependable, safe for regulated workflows, and ready for immediate integration into active research pipelines.

Cost Savings Without Performance Compromise

The investment required for new automation can delay modernization for many labs. Certified pre-owned liquid handlers dramatically reduce upfront expenses, often saving 40–70 percent compared to new units. These savings allow labs to:

- Expand automation across additional workflows

- Upgrade to higher-capacity or more advanced platforms

- Replace failing older systems without budget strain

- Support new programs without sacrificing other capital needs

Importantly, cost savings do not imply reduced performance. Certified systems—unlike used or as-is equipment—offer validated, reliable performance supported by professional service and warranty coverage.

For many labs, this cost-benefit ratio provides the flexibility needed to scale science responsibly.

OEM-Level Accuracy and Reliability

Precision is paramount in liquid handling. Even slight pipetting inconsistencies can lead to failed reactions, misleading data, or costly rework. Certified pre-owned liquid handling instruments deliver the same accuracy as new equipment through thorough calibration and testing.

Performance validation typically includes:

- Volume verification using gravimetric or photometric methods

- Tip alignment checks and deck calibration

- Pressure and flow analyses

- Pipetting head performance tests

- Cross-contamination and carryover assessments

Because certified equipment meets the same technical benchmarks as OEM units, labs can trust it to support sensitive protocols, from qPCR to NGS to automated screening workflows.

Integration with Existing Laboratory Automation Systems

Modern liquid handlers rarely operate in isolation. Instead, they fit within a larger automation ecosystem that includes:

- Robotic arms and plate movers

- Automated incubators

- Plate readers and washers

- Heating and cooling modules

- LIMS and ELN platforms

- Scheduling and workflow software

Most certified pre-owned systems support standard communication protocols and software integrations, enabling seamless interoperability. This compatibility allows for labs to increase throughput, maintain traceability, and connect different instruments without costly reconfigurations.

For labs building a phased automation strategy, certified systems make it easier to scale one component at a time.

Warranty and Technical Support You Can Trust

A significant advantage of certified automation is the ongoing support structure behind it. Reliable suppliers back their instruments with:

- Warranty coverage

- Performance guarantees

- Installation services

- Remote and on-site technical support

- Access to replacement parts

- Preventive maintenance options

This assurance provides peace of mind and ensures the system continues performing reliably for years. Technical support reduces downtime, protects workflow continuity, and saves labs from costly repairs.

Sustainability and Responsible Lab Investment

Sustainability is becoming an important priority across scientific organizations. Certified pre-owned automation supports environmental responsibility by:

- Extending the lifespan of high-value instruments

- Reducing electronic waste

- Minimizing manufacturing-related emissions

- Supporting circular laboratory procurement

Labs adopting greener operational practices benefit from lower ecological impact while maintaining high research standards.

Choosing the Right Partner for Certified Pre-Owned Automation

The success of a pre-owned automation investment depends heavily on the supplier’s validation standards, technical expertise, and service reputation. A trusted partner provides:

- Transparent certification processes

- Detailed validation reports

- Calibration documentation

- Workflow-specific consultation

- Ongoing support and maintenance

- Access to trained technicians

Working with the right supplier ensures that every instrument performs reliably and integrates smoothly into your existing environment.

The Smarter Path to High-Performance Automation

Certified pre-owned liquid handlers offer research facilities a powerful way to enhance throughput, accuracy, and consistency without overspending. With full validation, seamless integration, and strong warranty support, these systems deliver long-term value for labs of all sizes. For teams evaluating refurbished liquid handlers, certified systems remain the safest and most cost-effective approach to adopting automation.

Copia Scientific provides industry-trusted certified pre-owned automated liquid handling systems designed for performance, reliability, and cost efficiency. Build a future-ready automation strategy today. Contact us to get started.