Beam clamps provide a simple and efficient way to suspend a chain hoist from an overhead beam without permanent structural modifications. When chosen correctly, they offer flexibility and dependable performance for many lifting applications. However, selecting the wrong beam clamp can lead to instability, accelerated wear, or unsafe lifting conditions.

Before integrating a beam clamp into your lifting setup, it is important to evaluate several technical and operational factors. This listicle highlights the most important considerations to ensure safe, reliable lifting.

1. Working Load Limit (WLL)

The beam clamp must be rated equal to or higher than the chain hoist capacity and the maximum load being lifted. Always verify the stamped or labelled working load limit and never exceed manufacturer specifications.

2. Beam Flange Width Compatibility

Beam clamps are designed to fit specific flange width ranges. Choosing a clamp outside this range can prevent proper seating and load distribution. Confirm minimum and maximum flange dimensions before selection.

3. Beam Thickness and Structural Condition

The beam itself must be capable of supporting lifting forces. Inspect for cracks, deformation, corrosion, or excessive wear. Even a properly rated clamp cannot compensate for a compromised beam.

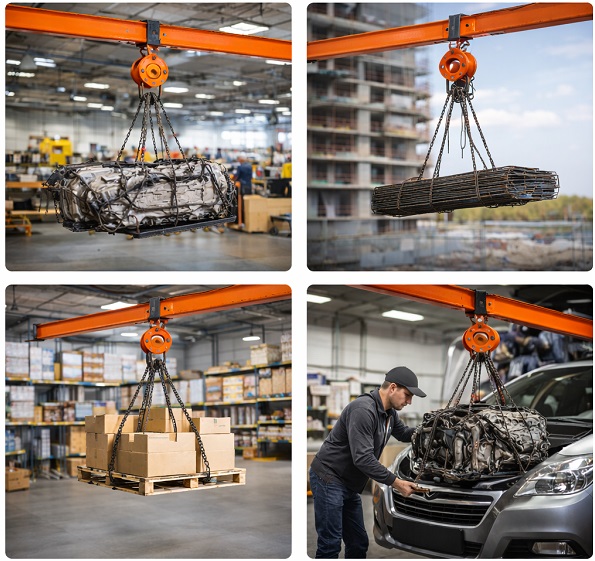

4. Clamp Design Type

Common designs include fixed beam clamps, adjustable beam clamps, and beam trolleys with integrated clamps. Fixed clamps suit stationary lifts, while adjustable or trolley-style clamps support repositioning along the beam.

5. Compatibility with Chain Hoist Attachment

The clamp’s suspension hole or eye must accommodate the hoist hook or shackle correctly. Poor fit can cause side loading or improper seating, reducing effective capacity.

6. Installation Method

Follow manufacturer installation instructions closely. Ensure the clamp sits square on the beam flange and fasteners are tightened to specified torque values. Incorrect installation is a common cause of slippage.

7. Load Direction and Alignment

Beam clamps are designed for vertical, in-line loading. Side loading or angled pulls reduce rated capacity and increase stress on components. Proper alignment preserves strength and stability.

8. Frequency of Use

Occasional lifting may allow for standard-duty clamps, while frequent or continuous lifting applications benefit from heavy-duty designs with higher fatigue resistance.

9. Operating Environment

Environmental conditions influence clamp longevity. Moisture, chemicals, high heat, or abrasive dust may require corrosion-resistant finishes or specialized materials.

10. Inspection and Maintenance Requirements

Beam clamps should be inspected regularly for cracks, worn threads, loose fasteners, or deformation. Damaged clamps must be removed from service immediately.

11. Compliance with Safety Standards

Quality beam clamps comply with recognized standards such as ASME. Look for manufacturer identification, load markings, and documentation to support regulatory and safety requirements.

Conclusion

Selecting the right beam clamp for a chain hoist involves more than matching sizes. Load rating, beam compatibility, installation quality, alignment, and operating conditions all affect safety and performance. By evaluating these eleven factors, operators can reduce risk, extend equipment life, and achieve more reliable lifting operations.